Exploring the significance of scheduled maintenance for diesel engines, this introduction sets the stage for a detailed discussion on the topic. It aims to captivate readers with valuable insights and essential information right from the start.

The following paragraph will delve deeper into the details and intricacies of the subject matter.

Importance of Regular Maintenance

Regular maintenance is crucial for diesel engines to ensure optimal performance, efficiency, and longevity. By following a scheduled maintenance plan, diesel engines can avoid costly repairs, breakdowns, and premature wear and tear.

Impact on Performance and Longevity

Regular maintenance plays a significant role in maintaining the performance and longevity of diesel engines. It helps in detecting potential issues early on, preventing major breakdowns, and ensuring that the engine operates at its best capacity. Proper maintenance also improves fuel efficiency and reduces emissions, contributing to a cleaner environment.

- Changing engine oil and filters regularly

- Inspecting and replacing air filters

- Checking and maintaining proper fluid levels

- Monitoring and maintaining cooling systems

- Inspecting and adjusting belts and hoses

Key Components to Maintain

Regular maintenance of key components in a diesel engine is crucial to ensure optimal performance and longevity. Neglecting maintenance can lead to costly repairs and breakdowns, impacting the overall efficiency of the engine.

Fuel Filters

Fuel filters play a vital role in removing contaminants and impurities from the fuel before it reaches the engine. Regularly changing fuel filters is essential to prevent clogging and ensure proper fuel flow, which can lead to engine misfires and reduced fuel efficiency.

Oil Filters

Oil filters help to remove dirt, debris, and contaminants from the engine oil, preventing premature wear and tear on engine components. Neglecting oil filter changes can result in poor lubrication, increased friction, and potential engine damage.

Cooling Systems

Cooling systems are responsible for regulating the engine temperature and preventing overheating. Regular maintenance of cooling systems, including coolant flushes and inspections, is crucial to avoid engine overheating, which can cause severe damage to the engine components.

Belts

Belts in a diesel engine, such as the serpentine belt, play a crucial role in driving various engine components like the alternator and water pump. Regular inspection and replacement of worn-out belts are essential to prevent belt failure, which can lead to engine stalling and costly repairs.

Benefits of Preventative Maintenance

Preventative maintenance for diesel engines offers numerous advantages over reactive repairs. By regularly servicing and monitoring key components, potential issues can be identified and addressed before they escalate into major problems, leading to costly repairs and downtime.

Cost Comparison

- Routine maintenance costs are significantly lower compared to major repairs resulting from neglect. By investing in preventative maintenance, businesses can save money in the long run and avoid expensive emergency repairs.

- Regularly scheduled maintenance can help extend the lifespan of diesel engines, reducing the need for premature replacements and saving on overall operational costs.

Prevention of Unexpected Breakdowns

- Preventative maintenance can help prevent unexpected breakdowns and minimize downtime. By proactively servicing and inspecting components, potential issues can be detected early and addressed, reducing the risk of unexpected failures.

- Regular maintenance can also improve the overall reliability and performance of diesel engines, ensuring smooth operations and reducing the likelihood of costly disruptions.

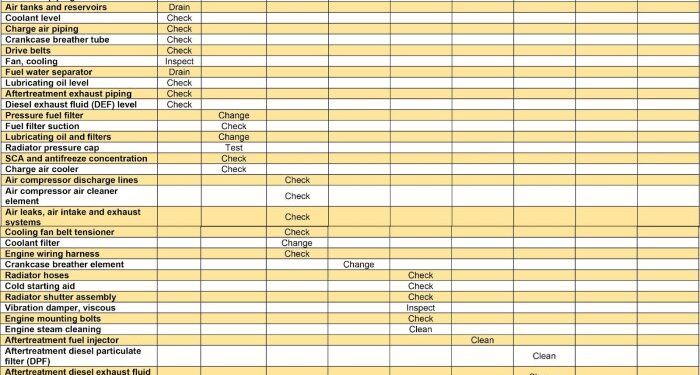

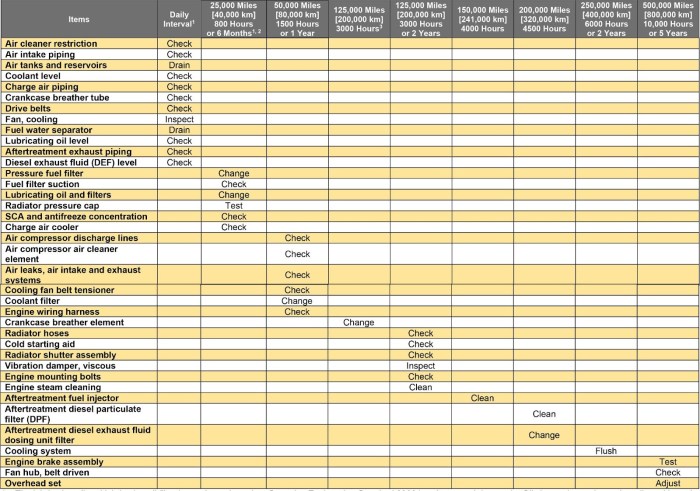

Maintenance Schedule and Best Practices

Regular maintenance is crucial for the optimal performance and longevity of diesel engines. By following a well-designed maintenance schedule and implementing best practices, you can prevent costly repairs and minimize downtime.

Designing an Ideal Maintenance Schedule

When it comes to designing a maintenance schedule for diesel engines, it is essential to consider both the usage of the engine and the manufacturer's recommendations. A general guideline is to perform routine maintenance tasks at regular intervals, such as every 50, 100, or 200 hours of operation.

However, heavy usage or harsh operating conditions may require more frequent maintenance checks.

Importance of Following a Maintenance Schedule

Adhering to a maintenance schedule is crucial to avoid unexpected breakdowns and costly repairs. By following the recommended maintenance intervals, you can identify potential issues early on and address them before they escalate into major problems. This proactive approach not only ensures the reliability of the engine but also helps to maintain its efficiency over time.

Best Practices for Maintaining Diesel Engines

Implementing best practices for diesel engine maintenance can further enhance its performance and longevity. Some key tips include:

- Regularly checking and changing the engine oil and filters to prevent build-up and ensure proper lubrication.

- Inspecting the cooling system, including the radiator and hoses, to prevent overheating and engine damage.

- Monitoring the fuel system for leaks or clogs, and replacing fuel filters as needed to maintain fuel efficiency.

- Checking the air intake system for debris or blockages, and replacing air filters to ensure proper airflow.

- Inspecting the belts, hoses, and other components for wear and tear, and replacing them as necessary to prevent failures.

- Conducting regular inspections of the engine components, such as the injectors and turbocharger, to detect any issues early on.

Final Summary

In conclusion, this discussion has shed light on the critical role that scheduled maintenance plays in ensuring the optimal performance and longevity of diesel engines. It has highlighted the key points and benefits that arise from adhering to a proactive maintenance approach.

Question Bank

Why is regular maintenance crucial for diesel engines?

Regular maintenance helps in detecting and addressing potential issues before they escalate, ensuring smooth operation and longevity of the engine.

What are some common maintenance tasks that need to be performed regularly?

Tasks like changing fuel filters, oil filters, inspecting cooling systems, and checking belts are essential for the upkeep of diesel engines.

What are the benefits of preventative maintenance over reactive repairs?

Preventative maintenance is cost-effective in the long run, reducing the chances of sudden breakdowns and minimizing downtime compared to reactive repairs.

How can following a maintenance schedule help avoid costly repairs?

Adhering to a maintenance schedule ensures timely inspections and replacements, preventing major issues that could lead to expensive repairs.

What are some best practices for maintaining diesel engines?

Regularly checking fluid levels, conducting routine inspections, and following manufacturer recommendations are key practices for optimal engine performance.